Fluid Flow And Heat Transfer In Wellbores Pdf Converter

Sep 19, 2016 - Wellbore heat exchanger Geothermal energy Energy conversion plant. And the flow rate of the selected working fluid, the thermal insulation.

• • 2k Downloads • Abstract The conventional geothermal power plants use the reinjection wells mostly to avoid the depletion of the geothermal reservoir gathering in the underground of the produced brine. Nevertheless, reinjection operations entail high economic costs and some risks. An alternative is the extraction of the heat without geothermal fluids production, the wellbore heat exchanger.

The goal of the present paper is the analysis of the power production of the wellbore heat exchanger (WBHX) in time and the comparison between two different conversion systems of the thermal energy into electrical: the organic ranking cycle (ORC) plant and the Stirling motor. The selected case study is the oil field of Villafortuna Trecate, a medium enthalpy geothermal resource.

The simulation results show a substantial decrease of the wellhead temperature in the first 6 months. After 1 year, the thermal power extracted with the WBHX is greater than 1.3 MW. The design parameters are 20 m 3/h for the flow rate, outlet temperature 100.38 °C and the inlet temperature is 40 °C. The R-C318 has been selected as working fluid in the ORC plant: the net electrical power is 121 kW.

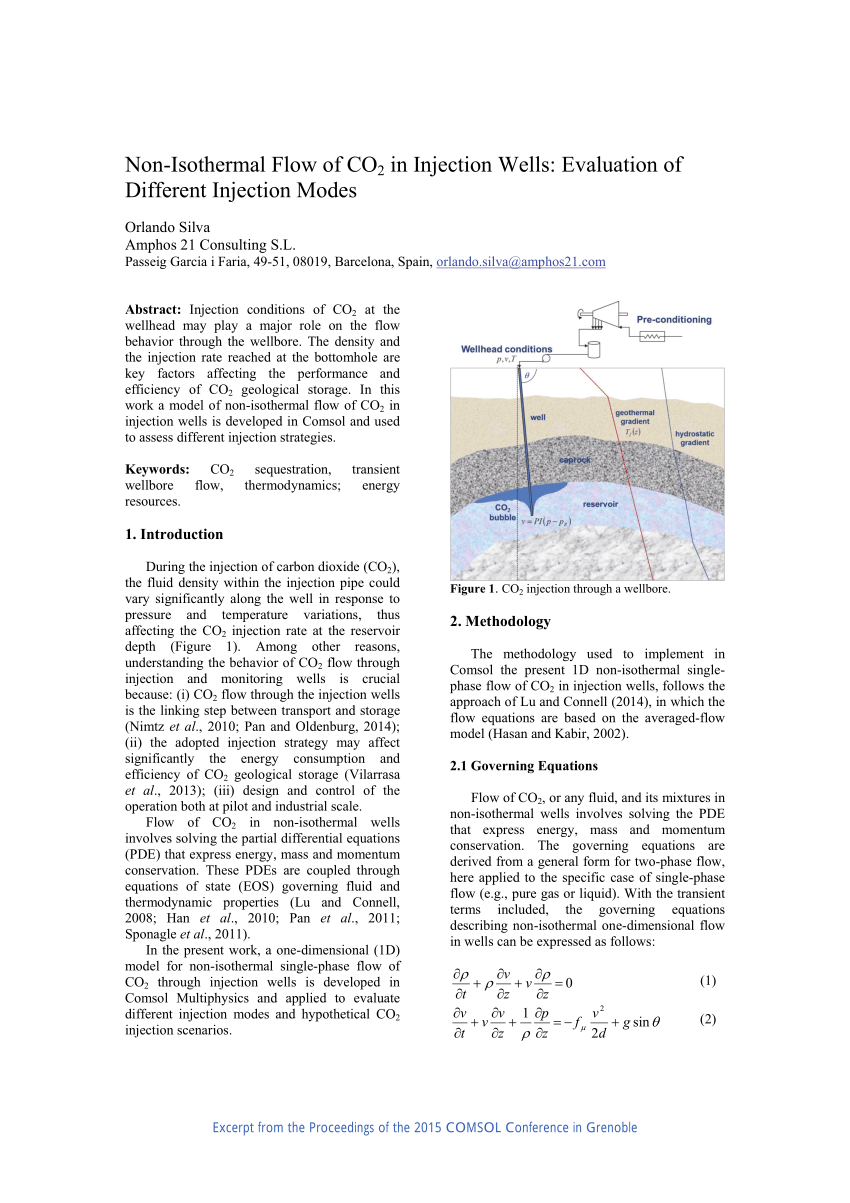

The air is the working fluid in the Stirling motor: the evaluated net electrical power is 152 kW. The Stirling engine has an efficiency greater than 41% compared to a system ORC. Fig. 1 WBHX: cross section and schematic Some researchers have studied the operative parameters that influence the feasibility and efficiency of the power plants based on WBHX. Among them are the geothermal gradient, the bottomhole temperature, the depth of the well, the properties and the flow rate of the selected working fluid, the thermal insulation between the two pipes that compose the heat exchanger (Kujawa et al.; Davis and Michaelides; Bu et al.; Cheng et al., ).

Several studies have proposed the use of the borehole exchangers to convert the abandoned oil wells into geothermal ones (Kujawa et al.; Zhang et al.; Wang et al.; Davis and Michaelides; Bu et al.; Cheng et al.; Templeton et al.; Cheng et al. Considering the drilling costs almost 25% of the total costs of the power plant (Hance ), and the high costs of closure of the oil fields, the use of the WBHX could be an economic advantage both for oil companies and for geothermal companies. The main weakness of the deep borehole heat exchanger is a low efficiency in heat recovery compared to a conventional geothermal technology. This is due to the lower mass flow rate and to the indirect exchange of heat, which causes a lower wellhead temperature.

However, the use of a WBHX could be a solution to extract heat from unconventional geothermal systems, such as magmatic or hypersaline reservoirs, where there are fluids with particular physical and chemical characteristics. The production of such fluids involve significant technical problems and high economic costs that can make non-profitable investment. The WBHX could be also an alternative to hydrofracking methods to exploit the hot dry rock reservoirs. In a previous study (Alimonti and Soldo ) has been proposed the application of the WBHX in an oil field. The selected case study is the Villafortuna Trecate field, a large hydrocarbon field still active but strongly depleted. The reservoir is a medium enthalpy geothermal resource (the bottomhole temperature is 160–170 °C) located between 5800 and 6100 m depth.

The feasibility of the WBHX has been studied using a numerical model. The target was the optimization of the WBHX to maximize the extracted heat. Two different heat carrier fluids were tested: diathermic oil and water, this latter has shown better heat transfer properties. Furthermore, the work by Melinder ( ) has shown that the values of thermal conductivity and volumetric heat capacity of the water are higher than for the fluids generally used as secondary working fluids.

The internal diameters of the pipes were modified until a configuration that ensures greater efficiency is found in the extraction of heat for the specific case study. The results of the study highlight also the importance to consider the change in fluid properties inside the WBHX. To evaluate the conversion capacity of the ORC plant a thermodynamic model has been built, which allow testing different working fluids. The R-C318 has been selected as the best working fluid considering the thermal efficiency.

Driver forsa fs 3120 win xp. Driver Processor Intel Atom N450 -(1.66Ghz,533Mhz fsb,512Kb L2 cache) Chipset Intel NM10 VGA Card Intel GMA 3150 Memory 1GB DDR2 Display 10.1 inch Card Reader 4 in 1 card reader (MMC, SD,MS,XD) Hard Drive 160GB Sata Camera 1.3MP LAN Card Built-in 10/100 Mbps LAN Modem 3.5G/ HSDPA (optional) Wireless LAN 802.11 A/G/B WLAN I/O Port 1 x card reader,3 x USB 2.0 1 x RJ-45 1 x Audio In, SPDIF/Audio Out 1 x Mic-In Audio Intel High Definition Audio Battery Li-Ion Battery 3 Cells (2470 mAh) Listrik 40W, 20 Volt Dimension 251 mm x 185 mm x 34mm Berat 1.2 kg (complete system).

Golodanie po voroshilovu metodika. In the proposed solution, a binary cycle plant with two stage of heat exchange converts the thermal power into electricity, as an alternative of a direct binary power plant (Davis and Michaelides; Bu et al.; Cheng et al. Starting from the results of the previous work another system to convert the thermal energy into electrical one has been studied: the Stirling motor. The goal is to compare the conversion capacity of the ORC plant with that of the Stirling motor.